03 Apr The Basics of Topcon Grading Machine Control

With Topcon grade control, you will always be one step ahead!

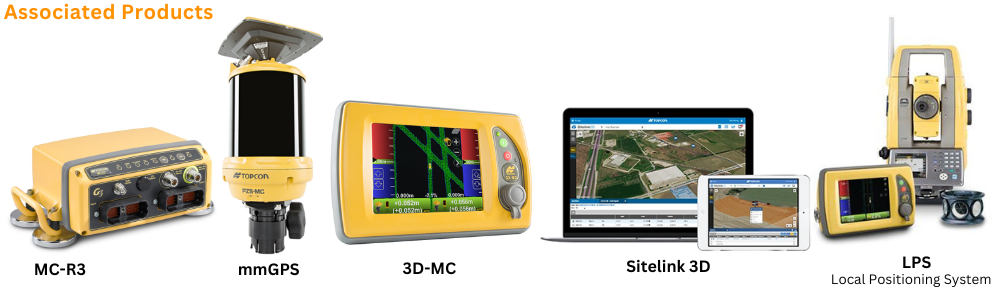

Topcon machine control hardware and software solutions were developed to determine a machine’s current position on the earth and compare it with the desired design surface. Using data from satellites or total stations and 3D models, the technology ensures that machine operators can accurately position machinery, check grade, automate equipment functions and collect data. Using a grade management system, contractors can topo the site themselves to verify the engineer’s quantities on the initial, 3-D contoured map of the existing site. This process is the comparison of the plan quantity versus takeoff quantity using construction software. After a contractor has completed their own accurate estimate, they can create a competitive bid and win the contract and save costs.

The contractor will then create a 3D model from the digital design, and then localize it and integrate the model into the on-site data collector and grade control machine. With the system ready to go, the contractor’s accuracy is improved, reducing the number of passes for successful job completion. Topcon grade control drastically eliminates the need for grade stakes and additional workers on the jobsite, even during the verification process.

Grade Control Systems

There are many grade control systems available in the market today:

With the entry level Topcon 2-D grade control system, it allows operators to set up a laser transmitter to cut to their desired grade, on both flat and sloping surfaces. The 2-D system uses angle sensors and rotational sensors to calculate the cross slope of either side of the blade, as well as a laser receiver to provide elevation control. Using a motor grader or dozer, the system allows stringline, previous pass or curb and gutter tracing. With the laser receivers, operators can use the system for fine grading plane surfaces. These systems often come with a control box that includes software with a powerful range of features specifically designed for lift and/or tilt control on dozers and motor graders.

With a 3-D grade control system, the job’s design elevations are input into the dozer’s or motor grader’s control box. A receiver on the machine reads the GPS signals received by an elevated antenna, as well as correctional data transmitted by a jobsite-based station to calculate an accurate, cutting-edge position. The control box’s computer compares the cutting-edge position to the design elevations and then displays cut-and-fill information. A Topcon 3-D system is best for complex contours. Automatic systems for both 2-D and 3-D even adjust the blade for the operator. Both methods allow you to achieve a precise height and angle, while using an exact amount of materials and manpower to complete the job.

The Topcon MMGPS (Millimeter GPS) combines the advantages of a laser with a GPS into one versatile, easy-to-use system. This technology improves grading accuracy up to 300 percent over most 3-D machine systems. The MMGPS transmitter sends out a wall of light 33 feet tall and up to 1,000 feet in diameter, and with a machine control sensor added to the existing GPS system, the vertical accuracy is enhanced considerably.

The Topcon robotic total stations is convenient when access to the sky is limited, such as on a project involving work inside a building or tunnel. They are 3-D positioning sensors for a 3-D grade control system. The sensor is an electro-mechanic and optical positioning device. It works anywhere a view of the sky is obstructed. Also, Topcon it is one of the most accurate positioning sensors available for 3-D grade control applications.

Grade Control WorkFlow

Since contractors are reducing their operating expenses with Topcon technology, grade control impacts them significantly throughout the entire work cycle. To see efficient return on investment, it’s important for contractors to execute flawless grade control workflow, a step-by-step process to help them complete jobs and maximize ROI while using grade control technology.

Step 1 – Setup/Topo: An engineer establishes four control points for a particular jobsite through specific measurements. The engineer will measure control points with a Topcon rover to establish the complete jobsite. Then, the engineer will create a topo of the jobsite. Wherever site development will occur, the engineer covers the entire jobsite to ensure all measurements are recorded. The topo will map out all of the elevation changes across the site, and the engineer will create the site design after all measurements are ensured and completed.

Step 2 – Magnet Design: The jobsite design establishes the location of all the structures that will be built, including underground utilities, parking lots and everything else the landowner wants to build on the site.

Step 3 – Takeoff and Estimation: In the takeoff and estimation portion of grade control workflow. Contractors will confirm the material that will be required to move using the grade management system. They will then compare the surfaces to make sure all of the engineer’s information is accurate and construction can begin based on the engineer’s measurements. Feet and tenths of a foot are measured on the map to paint the picture for the contractors, letting them know the distance of cut and fill. This helps contractors plan the equipment that will most efficiently move the material, allowing them to have the lowest cost per yard.

Step 4 – Model: A Topcon 3-D model software will allow contractors to build cut, fill maps and format the project to run on specific grade control software. The 3-D model will be then used for grading.

Step 5 – Import 3-D model to the crawler dozer: Using a simple USB, the contractor can upload the surface coordinates to the machine. With assistance from nVolve Solutions, a grade control specialist will support you as a contractor throughout the process.

Step 6 – Support: nVolve Solutions will be with you every step of the way to ensure grade control efficiency and results are achieved to increase the bottom line. At nVolve Solutions we have the parts on our shelves to ensure uptime, and dedicated specialists to help keep operations running smoothly.